This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 886866.

Injection moulding industry in Europe is in recession and there is a clear need to take actions in order to allow the recovery of this industry. Surface treatment of injected products offers the opportunity to add value to products and to enter in new industries. The automotive market is the most valuable injection moulding sector where surface treated (metallized) objects are used for functional parts (headlights) and aesthetic parts (decorative finishing). The current technology for the metallization process is usually vacuum deposition. The limitations of vacuum deposition are well known, where high investment in the technology, negative environmental impact and high-energy demands are the most prominent. A biotechnological solution for polymers metallization is a novel solution, where algae are used to deposit metals on selected surfaces. There are no similar solutions worldwide and the implementation of this technology will address several EU directives and guidelines with benefits in the industry and environmental protection. PolyBioMetal project will allow the commercialization of a disruptive green technology that will allow cost efficient, fast, simple and environmentally friendly metallization of polymers. PolyBioMetal is a novel and disruptive technology that uses algae for the metallization of polymers. This process will allow a sustainable and more competitive metallization process.

During the feasibility study a new product opportunity occurred. The technological aspects of our technology proved to be challenging for products (car parts) that has to be aesthetic, functional and also durable. Although doable, to fulfill all these aspects, the technological and financial challenge is substantial. However, we realized that our technology is much more appropriate for special glass surface treatment.

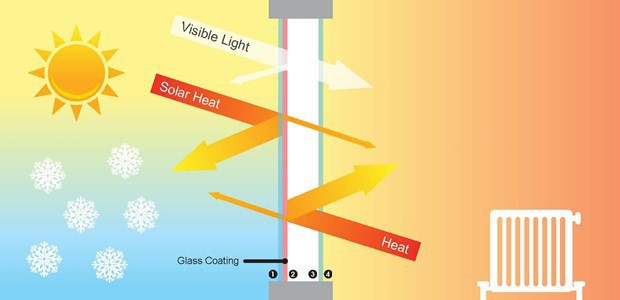

The result is a glass sheet that is able to pass through most of the visible sun spectrum and block IR radiation through the glass.

The need for novel solutions and innovations in glass surface functionalization came from industrial leaders in this segment that contacted us during the feasibility study. Coated glasses are extremely important for example for energy efficiency of buildings. Currently the trend for energetically efficient building construction and national regulations require novel materials that add up to overall energetic efficiency. This is paving the way to growth of the glass coating industry. The current technology requires very complex and expensive equipment and the end products have many times several flaws that we can address with our technology. We are also indirectly solving the problem of end users that wants as much sunlight indoor as possible and as big heat reflection as possible at the same time. The final product have much thinner metalized surface in comparison to the automotive parts that we addressed at the beginning. Also, the aesthetics have another dimension; car parts should have a visible, very homogeneous and reflecting surface. Glass on the other hand should have a homogeneous metalized surface that is transparent and possibly completely invisible.

The innovation process is led by Augmentech.

Find out more: info@augmentech.si

Augmentech, d.o.o.

Ulica 15. maja 17

6000 Koper